Aws Cwi Things To Know Before You Buy

Aws Cwi Things To Know Before You Buy

Blog Article

Little Known Questions About Aws Cwi.

Table of ContentsThe Main Principles Of Aws Cwi The smart Trick of Aws Cwi That Nobody is DiscussingAws Cwi - QuestionsRumored Buzz on Aws CwiAws Cwi Things To Know Before You Get This

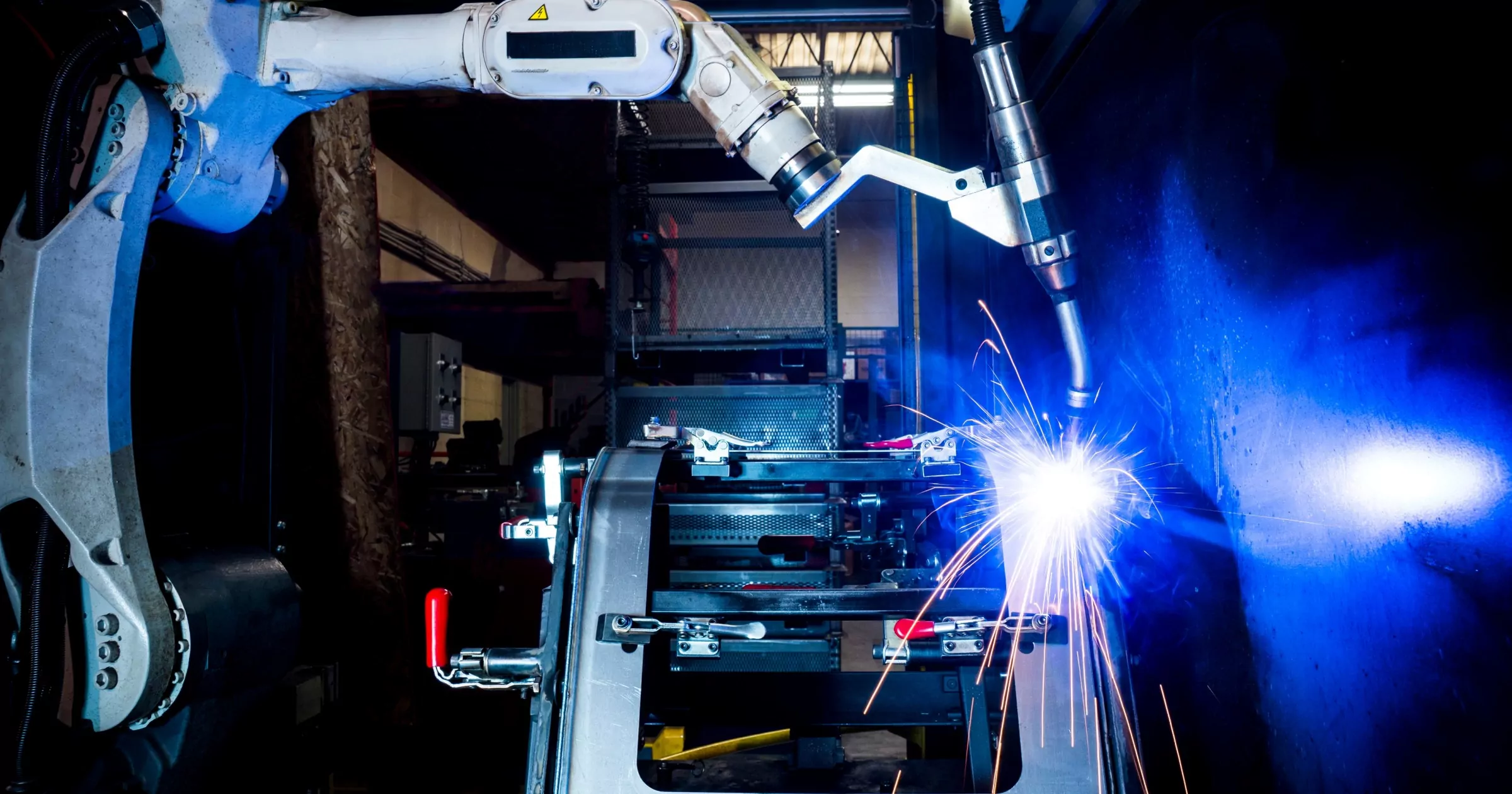

Third-party quality assurance inspection of steel manufacture centers on welding examination, as well as inspection of bolting and painting of structural steel. KTA's steel inspectors offer Quality assurance (QC) inspectors to supplement producer's/ service provider's internal QC staff and on tasks that mandate preserving the services of a certified assessor (e.g., CWI) employed by an independent examination company.Assessors conduct aesthetic examinations of material for correspondence with the approved specifications, strategies and codes, as well as verification of Qualified Material Test Records (CMTR) for products made use of. Materials and elements are observed at essential factors along the production process in both steel mills and steel manufacture shops. KTA's qualified welding examiners also witness welder and welding treatment certification examinations as applicable to the range of the project.

Steel construction examination services likewise regularly include performing non-destructive testing (NDT), likewise referred to as non-destructive exam (NDE), including Magnetic Particle Checking (MT), Ultrasonic Testing (UT) and Fluid Penetrant Evaluating (PT) (Welding Inspector). Assessments occur in steel mills and fabrication stores throughout the United States and on-site in the field and include all ranges of frameworks including bridges, arenas, buildings, towers, posts, and sign frameworks

The Greatest Guide To Aws Cwi

KTA offers evaluation services for the construction of bridge girders, bearings, grid deck, sign structures, light and traffic posts, pedestrian bridges, and other freeway elements. KTA additionally supplies these services for construction of structural steel for structures, storage tanks and pipes. KTA's inspection solutions consist of finishing evaluations covering surface prep work, painting, galvanizing, and metalizing.

KTA's philosophy is to respond rapidly to customers' demands, match the best inspector to the task, and give the requisite paperwork. KTA has the support employees to offer technological consulting to the area employees and to the client. KTA has experts offered to speak with on welding, NDT and coverings.

Come sign up with an outstanding group in an interesting, quick paced, and ever-growing industry! We are looking for a CWI's and/or NDT Level II certified Welding Inspectors from in and around the Lithia Springs, GA location!

The Best Strategy To Use For Aws Cwi

Semiconductor, Consumer Products, Biography & Biopharmaceutical, and so on. Ideal candidate will certainly have high pureness piping evaluation experience. Present AWS certs are preferred. CWI's and NDT Level II's highly urged to use.

Pro QC's third-party welding inspection services consist of: File Review Witness Inspections Visual Inspections Dimensional Inspections Non-Destructive Testing (NDT) Others Our welding inspection reports are delivered within 1 day and document all evaluation points pertinent to top quality, including all recognized weld blemishes and electronic pictures (AWS CWI) (https://hubpages.com/@awscw1w3lding). Pro QC's group of examiners supplies third-party welding evaluations around the world, in China, India, Indonesia, Malaysia, Thailand, Vietnam, Singapore, South Korea, Turkey, UAE, Jordan, Egypt, South Africa, Morocco, Algeria, Tunisia, France, Germany, Italy, Czechia, Hungary, Spain, Sweden, Portugal, the Netherlands, Denmark, Norway, Finland, Belgium, the United Kingdom, Serbia, Greece, Romania, Bulgaria, Ukraine, Slovenia, Slovakia, Poland, Croatia, Russia, Lithuania, the United States, Mexico, copyright, Brazil, Peru, and much more nations

Inspection of the welding job is essential for appropriate top quality When your firm is taking care of major projects with demands for 3rd event independent welding assessment, we give outstanding welding witness evaluation services to validate that welding has actually been performed according to most used welding requirements and specs. AQSS executes welding evaluation solutions for customers from a variety of industries.

Excitement About Aws Cwi

Not following effectively qualified welding procedures typically results in a weld of poor top quality, which can raise the fabrication's chance of failure under desired solution problems. By examining for problems, our assessors can this article assist customers make certain that their welds meet appropriate standards of quality control (AWS CWI). Weld inspections are performed for several factors, the most typical of which is to determine whether the weld is of appropriate top quality for its intended application

Our welding examiners have actually the required accreditations with years of experience with assessment and are familiar with most applied welding requirements and specs. AQSS has CWI accredited examiners.

Aws Cwi Things To Know Before You Buy

Weld evaluation of laser and electron light beam bonded components normally follows 3 distinctive courses: aesthetic assessment; destructive screening; and non-destructive testing (NDT). includes checking out a weld with the naked eye and/or with some level of zoom. Usually, our assessors are looking for cracks, pits, surface pores, undercut, underfill, missed out on joints, and various other elements of the weld.

Examples can likewise be taken at periods throughout the production process or at the end of the run. Destructive testing examples are exactly reduced, machined, ground, and brightened to a mirror-like coating. An acid etch is then related to visually draw out the weld, and the sample is then checked under a microscopic lense.

Report this page